Prevent Scratches and Stains with High-Performance Ceramic Coating Denver

Prevent Scratches and Stains with High-Performance Ceramic Coating Denver

Blog Article

A Comprehensive Guide to the Types of Ceramic Finishing on the marketplace

Ceramic coverings have actually arised as a crucial solution throughout numerous industries due to their distinct buildings and applications. As we discover the unique features and applications of these finishes, the ramifications for efficiency and durability come to be progressively apparent, increasing concerns concerning which type may finest fit your demands.

Recognizing Ceramic Coatings

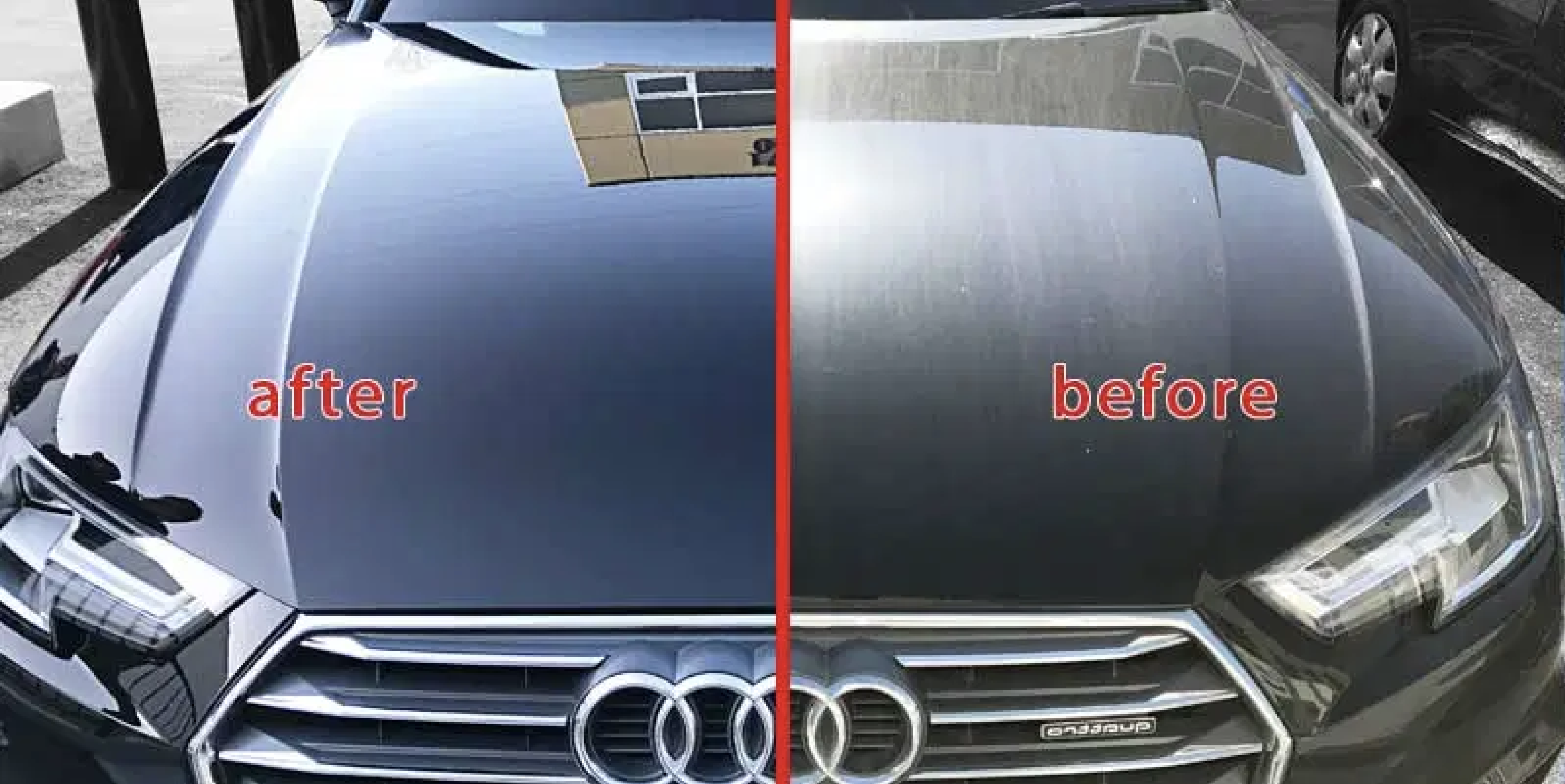

Ceramic coverings are sophisticated protective services that have obtained appeal in numerous sectors, specifically in automotive and aerospace applications. These coverings contain a liquid polymer that, when cured, creates a sturdy, hydrophobic layer externally of the substratum. This layer supplies improved resistance to environmental contaminants, UV radiation, and chemical exposure, therefore expanding the life and visual charm of the underlying material.

The fundamental part of ceramic layers is silica, which adds to their firmness and toughness. The application procedure normally includes surface prep work, application of the layer, and healing, which can be achieved through warm or UV light. Once healed, ceramic coatings display phenomenal bonding properties, enabling them to adhere highly to a variety of surface areas, including steels, plastics, and glass.

Along with their protective attributes, ceramic layers additionally provide ease of upkeep. Their hydrophobic nature decreases the adherence of dust and gunk, making cleansing less complex and much less frequent. Generally, the adoption of ceramic coverings stands for a considerable advancement in surface area protection modern technology, offering both useful and aesthetic advantages throughout several fields.

Types of Ceramic Coatings

Numerous types of ceramic layers are offered, each made to meet certain performance requirements and applications. One of the most usual types consist of:

Silica-based Coatings, these coatings mainly contain silicon dioxide and are known for their toughness and chemical resistance. They are widely made use of in commercial and automotive applications.

Titanium Dioxide Coatings: Popular for their photocatalytic properties, titanium dioxide finishes are often applied in atmospheres where self-cleaning and antifungal properties are desirable, such as in building materials and automobile surfaces.

Zirconia Coatings are defined by their high-temperature security and thermal resistance, zirconia layers are utilized in applications such as turbine engines and high-performance automobile elements.

Alumina Coatings, Exhibiting outstanding hardness and thermal stability, alumina finishings are often utilized in wear-resistant applications, consisting of cutting tools and industrial machinery.

Hybrid Coatings:Combining the homes of different materials, hybrid coatings offer enhanced efficiency features, making them appropriate for special and requiring applications.

Each type of ceramic finishing offers distinct objectives, permitting individuals to choose the most appropriate solution based upon particular environmental problems and performance requirements.

Benefits of Ceramic Coatings

Along with toughness, ceramic finishes supply exceptional hydrophobic residential properties, permitting easy cleansing and maintenance. This water-repellent nature decreases the adherence of dirt, grime, and various other impurities, which can extend the visual charm and functionality of the surface area. In addition, ceramic layers can dramatically improve thermal resistance, making them optimal for applications that endure heats.

Another significant benefit is their capacity to enhance surface area firmness. This raised firmness can lead to minimized wear and tear, inevitably extending the life expectancy of see it here the coated material. Ceramic finishes can add to energy effectiveness by mirroring heat, which is specifically beneficial in industrial and automobile setups. On the whole, the various advantages of ceramic finishings make them an important investment for various applications, making certain optimal performance and protection.

Application Refine

When using ceramic finishings, a careful method is important to accomplish optimum results. A clean surface guarantees proper bond of the finish.

As soon as the surface is prepped, the following step is to use the ceramic coating. The coating must be applied in slim layers, as thicker applications can lead to unequal coatings.

After application, the layer needs a specific healing time, usually varying from a few hours to a complete day, depending on the item. Throughout this time around, it is essential to avoid direct exposure to moisture or my company pollutants. A mild buffing may be necessary after treating to improve the gloss and remove any type of high spots. Following these actions faithfully will make the most of the performance and longevity of the ceramic finishing, giving a resilient safety layer for the surface area.

Maintenance and Durability

To make certain the durability and efficiency of a ceramic covering, normal upkeep is vital. Ceramic finishings, known for their durability and safety qualities, require specific treatment routines to optimize their lifespan and efficiency.

Along with normal washing, routine inspections are critical. Search for indicators of wear or damage, such as hydrophobic properties decreasing or surface area imperfections. If needed, a light gloss may be related to renew the covering without removing it away.

Moreover, the application of a booster spray can boost the covering's hydrophobic impacts and recover its gloss. This is particularly helpful for coatings that have remained in usage for an extended duration. Inevitably, by sticking to these maintenance techniques, one can significantly prolong the life of a ceramic finishing, guaranteeing that it remains to give optimum protection against environmental factors and maintain the aesthetic appeal of the car.

Verdict

To conclude, ceramic coatings stand for a versatile option for an array of applications, providing a selection of types such as silica, titanium dioxide, zirconia, and alumina. Each kind offers distinct advantages, consisting of resilience, self-cleaning buildings, high-temperature stability, and use resistance. The application procedure and recurring upkeep play crucial functions in making the most of the durability and efficiency of these layers. Overall, ceramic finishings add significantly to improving the toughness and capability of various surfaces across multiple industries.

Ceramic finishes have emerged as a pivotal remedy throughout different markets due to their distinct homes and applications.Ceramic finishings are advanced safety remedies that have actually acquired popularity in various sectors, specifically in aerospace and automobile go to these guys applications. Ceramic coverings can significantly boost thermal resistance, making them suitable for applications that withstand high temperatures.

On the whole, the various advantages of ceramic layers make them a useful investment for numerous applications, guaranteeing optimal efficiency and protection.

In verdict, ceramic finishings stand for a flexible solution for a variety of applications, offering a range of types such as silica, titanium dioxide, alumina, and zirconia.

Report this page